Originally appeared on The Human Readable Blog, by TEKLYNX.

Partner Blog BY: JENNA WAGNER / TEKLYNX

Manufacturers today are part of a global supply chain, sometimes specializing in one product or process. In a vast supply chain made up of contract manufacturers, suppliers, warehousing providers, and distribution specialists, labeling is the common language that allows every link in the supply chain to work together.

Manufacturers who have multiple upstream suppliers understand that labels on incoming goods must be accurate. Supplier labeling is a critical component of an efficient supply chain, and a unified supplier labeling system can have a big impact on overall efficiency and the bottom line. With the right tools, such as centralized labeling platforms and mobile device management solutions, businesses can ensure that suppliers across regions follow consistent labeling standards while maintaining flexibility

3 types of inconsistent or outdated supplier labeling systems:

Companies without a unified supplier labeling system are likely managing a hodgepodge of label files, data, and software.

- Some manufacturers resort to simply sharing label files or data to their many suppliers for printing. When labels are updated or changed, the files must be manually re-sent. Not only is this time consuming, it opens the door to human error and the risk of using outdated data.

- Other manufacturers might be managing a mismatched software environment, leveraging different brands of labeling software with each supplier. This is often the case when the supplier labeling system has grown over the years without much strategic direction.

- Some manufacturers are using their own custom-developed supplier labeling system. While custom-developed software starts out as the perfect fit, it can be difficult and expensive to keep it compatible with modern technology.

All the above supplier labeling scenarios can lead to inaccurately labeled products, resulting in expensive and unnecessary supply chain bottlenecks.

RISKS OF INACCURATE SUPPLIER LABELING:

- Inventory is the heartbeat of manufacturing, and mistakes can cause serious production delays. If inaccurate labels are not caught early, they can lead to inaccurate inventory.

- When automatic identification is impossible due to bad labels, employees must manually identify products. Manual product identification takes time and employees are likely to make mistakes.

- When mistakes are caught, products must either be returned to the supplier or relabeled. Returns and relabeling waste time and resources.

Inaccurate supplier labeling causes significant inefficiencies in the inventory receiving process. An inefficient process means more time, space, and labor are required to manage incoming inventory.

With a unified supplier labeling system, companies experience much lower risk for labeling errors from their suppliers. The best part? No local software installations!

How does a unified supplier labeling system work?

- Smart label templates are designed and maintained in-house, and every change must pass your customizable approval process. Only approved label templates can be printed.

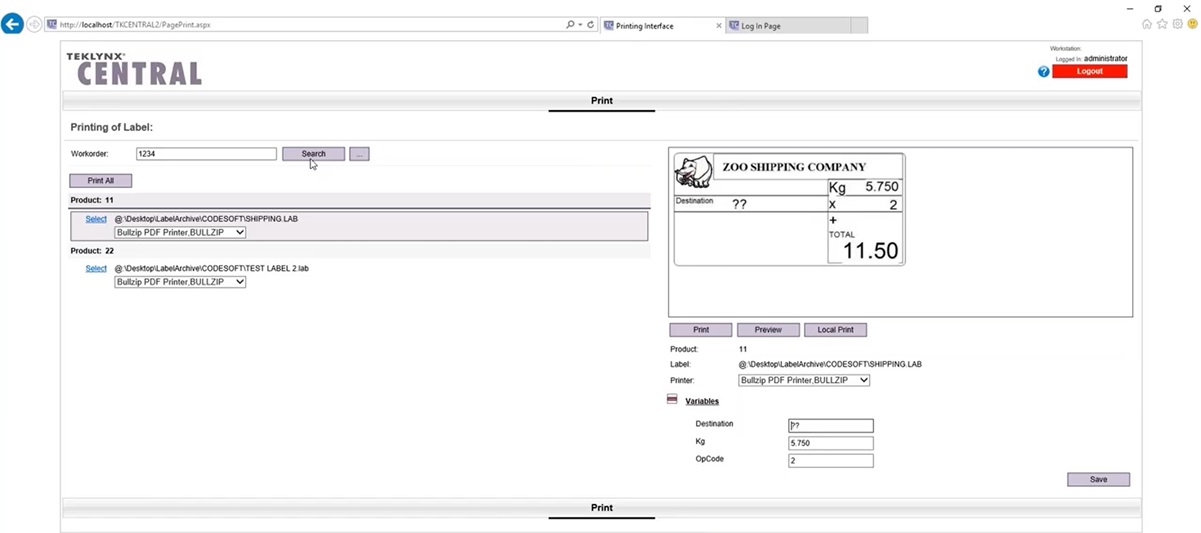

- You create simple, streamlined printing interfaces via a web browser that are secured with a username and password. Each supplier can only access the approved labels that are associated with that supplier. No local software installations or sending files back and forth required!

- Seamless integration with business systems and databases provides accurate real-time data for every label printed.

- Every label print job is tracked, including both internal print jobs and external supplier print jobs. Detailed reporting sets you up for success in the event of an audit.

The supplier labeling system is centrally managed by your company. It can be hosted on-premise or in the cloud. Web-based label printing portals are published and can be branded with your company’s logo. Each supplier has secure access to approved label templates that automatically pull in real-time data from your business system!

BENEFITS OF UNIFIED SUPPLIER LABELING:

- Only accurate and real-time label data is printed, thanks to seamless integration with the necessary business systems.

- Fewer labeling errors means the inventory receiving process is automated and efficient.

- Inventory records are accurate, reducing the risk of production delays.

- Maximum security with customizable user permissions.

- Maximum traceability and ability to report on all past label changes and print jobs.

- Adding new suppliers is quick and easy, eliminating a burden for your IT team!

The best way to modernize your supplier labeling is to implement a unified supplier labeling system. TEKLYNX CENTRAL label management solution from TEKLYNX provides an easy-to-manage all-in-one solution. With modules for label design, label security, web browser-based label printing, and label print automation, TEKLYNX CENTRAL meets manufacturers’ needs for supplier labeling and helps companies around the world barcode better.

###