Originally appeared on The Human Readable Blog, by TEKLYNX.

Partner Blog BY: LINDSAY SCHUEMANN / TEKLYNX

At any step in the cannabis supply chain, your labeling system should allow for full control and traceability, from seed to sale. Implementing lean principles and labeling best practices across the cannabis supply chain can help you streamline your seed-to-sale labeling process and help you gain control.

Cultivation

Whether you have your own vertically integrated cannabis operation or you’re growing for customers, implementing the proper cannabis labeling processes from the beginning is crucial. Like many industries, the cannabis industry is faced with strict labeling regulations for the variety of products offered and each step in your cannabis supply chain process should have secure and streamlined labeling processes. From a seedling to a flower and everything in between, each stage should be tagged and traced. RFID tags are required in some states, and can be an efficient tool to utilize as they can be fastened to plants for easy location tracking across a grow house floor. Having this backlog of information allows for full visibility into the cultivation stage in the cannabis supply chain process, especially when paired with mobile device management solutions that help ensure accurate, secure, and compliant data handling across teams and facilities.

A labeling system that can integrate with METRC, BioTrack, Leaf Data, or other seed -to-sale software solutions is a great starting point. In implementing these, you are ensuring that whatever cannabis labeling regulations your business faces, you can rely on your software to help create compliant labels throughout the cannabis supply chain.

Lab Testing

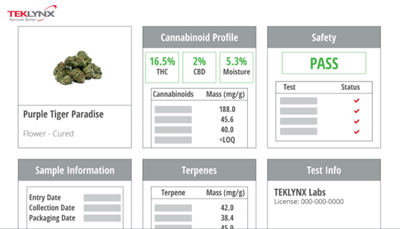

This includes:

- Pass/fail chemical testing

- Final date of testing & packaging

- Identification of testing lab

- Cannabinoid profile & potency levels

An efficient way to display lab results on product labels is with a QR code, so the consumer can review the independent lab’s certificate of analysis. QR codes have the flexibility of including a lot of information in a small space.

Learn more with our Cannabis Labeling from Seed to Sale infographic.

Processing & Production

On top of lab results, a lot more information needs to go on a cannabis label. Whether you’re producing pre-rolls, packaged flower, edibles, beverages, topicals, or cartridges, your cannabis products must be labeled correctly and done so in a preferably efficient manner.

TEKLYNX software can simplify this process by importing high-resolution artwork and leveraging dynamic barcodes, rfid technology, and variable data, having easy-to-use barcode creation wizards for 1D & 2D barcodes, and offering WYSIWYG (What You See Is What You Get) printing. Database integrations with seed to sale software solutions are an efficient way to help streamline your processing and production phase, allowing you to populate variable data from an existing database.

Integrating existing databases with your label templates can save time and money in the cannabis supply chain. Bringing labeling in-house and printing labels on-demand can enable cannabis cultivators, processors, and dispensers the ability to print labels as needed and make changes as they go, eliminating the risk of wasting obsolete pre-printed label stock and allows for more flexibility in your label design process. Bringing labeling in-house and printing labels on-demand can also reduce the risk of non-compliancy if a labeling regulation shifts and your company is using pre-printed and now out of date labels.

Read our How to Create Compliant Cannabis Labels On-Demand blog.

Distribution

A critical step in cannabis supply chain labeling is distribution. The ability to manage and distribute inventory efficiently is crucial and implementing label design software that responds to consumer and industry demands can help. Your cannabis labeling software should have the capabilities of creating packaging & shipping labels, case & pallet labels, as well as inventory labels.

Leveraging your barcode labeling software to create important documents is a great way to remove the need for a separate tool to create pack lists, case labels, and purchase orders. GridField is a tool built within CODESOFT that can manipulate, create, and alter dynamic labels quickly and easily.

With an integrated cannabis labeling process in place, you can automatically trigger label printing by an action in your seed-to-sale system or by monitoring a database. If your business is operating with multiple locations and leveraging several seed-to-sale tracking solutions, TEKLYNX CENTRAL is a great tool to help streamline complexity, as well as easily and securely share approved label files across the cannabis supply chain.

Cannabis Retailer

By leveraging a robust and efficient barcode labeling solution in your cannabis labeling supply chain, you’re able to accurately display product information, lab results, and company branding, all while complying to regulatory requirements that may vary by state, province, or country.

Check out our Barcode Labeling for the Cannabis Industry video:

Interested in learning more? Click here to read our eBook, On-Demand Labeling for the Cannabis Industry.

Navigating cannabis supply chain labeling requirements doesn’t have to be hard. Let TEKLYNX help.

Check out our Cannabis Industry page to learn the ins and outs of cannabis labeling.

Get in touch today to learn more.

###